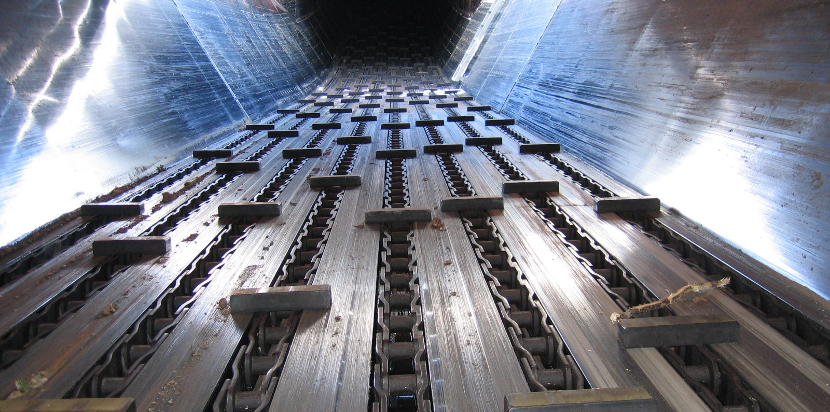

If your conveyor chain often runs on metal or plastic wear strips then it’s important to carefully consider both the hardness of the surfaces and the finished condition of the conveyor chain link plates.

When a metal conveyor chain wear strip is too hard it can cause the conveyor chain side plates to wear quickly which will dramatically reduce the life of the chain.

If you’re running your conveyor chain on a plastic wear strip, then you can increase the life of your wear strip by using surface tumbling to remove all the sharp edges of the conveyor chain link plates.

What is surface tumbling?

Surface tumbling is a simple process which involves placing finished conveyor chain link plates in a container where they are 'barrelled' in a special abrasive media to remove any sharp edges.

The end result is smoother plates with a significantly longer wear life.

If you’re looking to increase the life of your plastic conveyor chain wear strips then we highly recommend that you ask for your conveyor chain side plates to be tumbled.

The potential savings in replacement wear strips, in costly machine downtime and in engineer labour costs will far exceed the small increase in the basic price of the 'tumbled' conveyor chain.